How To Get Rid Of Common Errors In Concrete Floor Slab Construction

To get rid of common errors in concrete floor slab construction, various steps like perfect base preparation, mix design, placement, finishing, and curing should be taken.

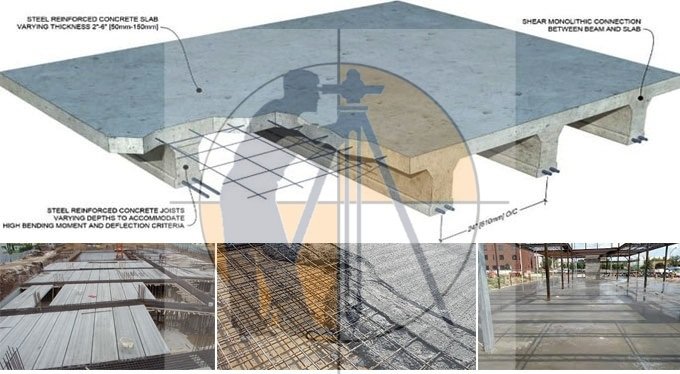

Typical concrete floor slab thickness in residential construction should be 4 inches. In case the concrete has to sustain extreme loads irregularly, the thickness should be five to six inches; as for instance, motor homes or garbage trucks.

To arrange the base, the ground level should be dug according to the perfect depth to provide for the slab thickness. Take out all organic material and large hard objects like stones and tree roots to a depth of minimum 4 inches. If it is required to develop the grade, apply gravel or sandy soil, and compress the final base with a vibratory plate or equivalent device.

The edge is built up with any straight material that can be fixed into position. If case of constant non-availability of straight lumber, plastic or metal forms should be used. Fix a string line with grade stakes or batter boards to provide a square, level reference prior to place the form-work.

Other Post

-

Transition Curve In Highways – Purpose-Requirements-Example

-

How To Find The Coordinates Of Point P With The Help Of Point A & B

For the concrete mix, it should satisfy the compressive strength requirements (normally 3000 pounds per square inch) devoid of measures that lead to extreme shrinkage. The shrinkage and cracking are increased because of the existence of water, a plasticize should be used to attain required slump.

Also provide fibers to check plastic shrinkage cracking. Greater strength and entrained air are necessary for exterior slabs susceptible to freezing weather or deicing chemicals.

It is suggested not to add water at the job site more than 1 to 2 gallons per cubic yard. In case, extra slump is essential, take advice from the mixer truck driver concerning the quantity of water to be included devoid of taking the concrete out of specification.

Spread the concrete across the slab area as close to its final position as possible, and then rake it into exact location. Hardens low-slump mixes manually with a vibrator or apply a vibratory screed. Complete with the least force and strokes of the float required to attain a smooth surface.

Develop control joints no farther apart than 24 to 30 times the slab thickness and at no time exceeding 15 feet along both the width and length of the slab by pushing a 1-inch deep grooving tool into the surface.

To keep Joint spacing more than 15 feet, different types of load transfer devices should be used which range from dowels or dowel plates. For slabs with long joint spacing or no joints, steel reinforcement will be suitable.

It will raise the chances for random cracking, but will maintain cracks firmly to keep up superior structural performance.

The curing process should be initiated when the finished surface can counter damage. The concrete should not be enabled to freeze or dry out. Arrange a curing compound over the surface, or apply proper moist curing.

In case of freezing, the slab should be wrapped with an insulator, like insulating blankets or a 4-inch-thick layer of straw that is weighted down so that it can’t blow away. Unless the concrete attains a strength of minimum 500 psi, put the insulator in place. It normally happens within a few days.

Surveying & Architects A unique platform of Civil Engineering

Surveying & Architects A unique platform of Civil Engineering