Seven Basic Rules For Providing Lap Splice In Column And Slab

Now, let us go through Seven basic rules while lapping the Rebars in Columns.

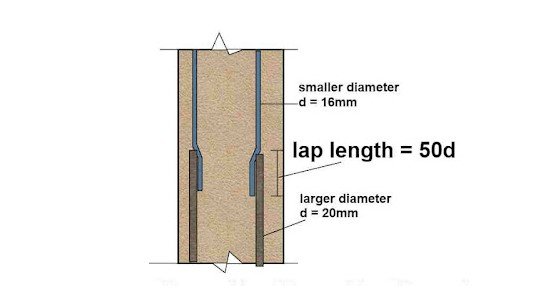

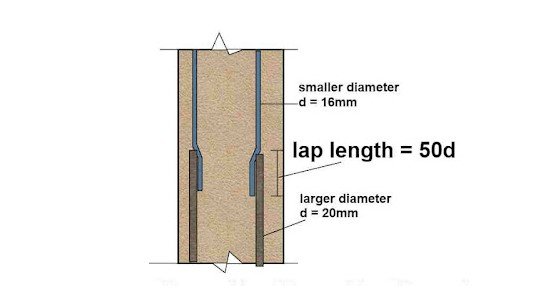

1. Lap length diameter:

When we extend the top bar of the column from the bottom bar, having an unequal diameter, then the lap length is calculated for the smaller dia. bar.

For eg., if the upper bar of 16mm dia. is lapped with a lower bar of 20mm dia., and if the lap length is taken as 50d, then

Lap length 50d = 50 × 16mm = 800mm. 👈correct

Lap length 50d = 50 × 20mm = 1000mm 👈 incorrect

Learn More

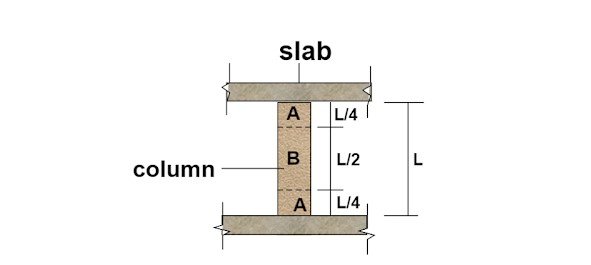

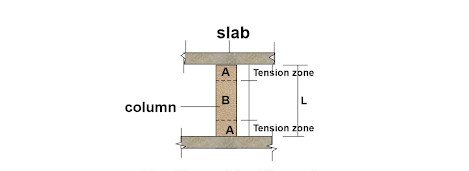

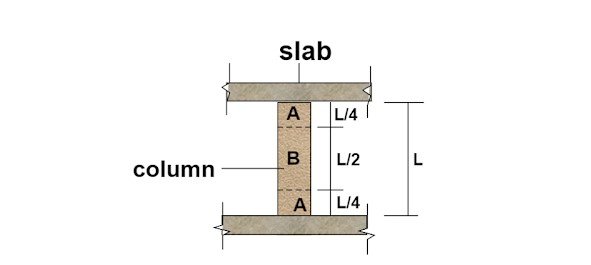

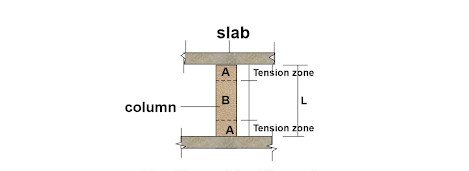

2. Lapping zone :

When we provide lapping in a column, all the rebars should be lapped in Zone-Bas shown in the drawing. The top and bottom portion of the column, i.e.zone-A ( L/4 length ) should be avoided as there will be a maximum moment in this zone due to lateral forces acting on the column.

If the length of the column is L, then the L/4 length from the top & bottom of the column is categorized as tension zone A and the center L/2 length of the column (zone B ) is considered a safe area for the lapping purpose.

Learn More

-

-

-

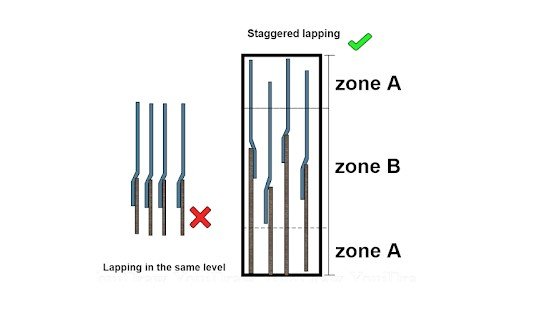

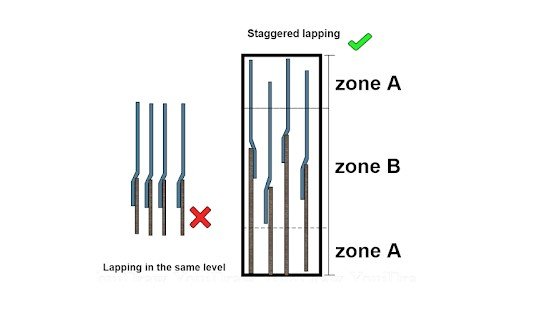

3. Staggered bar :

All the bars that are lapped should be staggered within zone B as shown in the above drawing. In any case, not more than 50% of rebars should be lapped in the same level. If all the column bars are lapped at the same level, it leads to the failure of the column.

4. Stirrup spacing :

The spacing of the stirrups in the lapping zone should be minimum when compared to the regular column c/c stirrup spacing.

If the designed regular spacing for the column stirrup is 175 c/c, then the spacing of stirrups in the lapping zone maybe 150 c/c or 125 c/c as according to the column design.

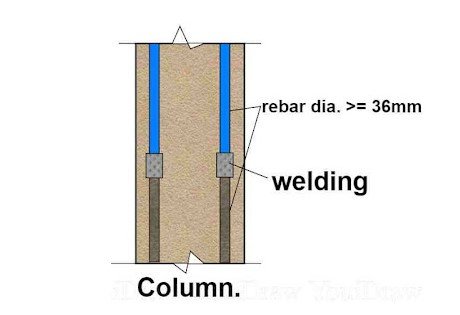

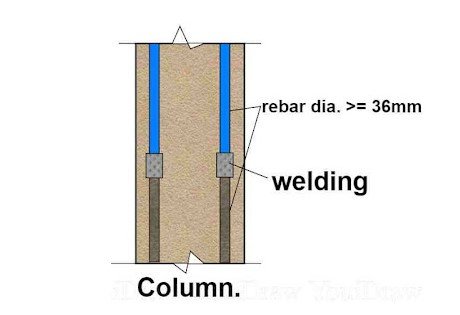

5. Welding the rebar :

As per IS code, if the bar diameter is greater than or equal to 36mm, then you should consider welding those bars instead of lapping. If welding is not possible, then you can lap these bars with an additional spiral of 6mm bar at the splice length.

6. Joggle length :

For the rebars of diameter greater than 12mm, you can consider providing a joggle of 1 in 6. That means if the bar dia. is 20mm then the length of the joggled part of the bar can be calculated as

J = 6 ×Diameter of rebar

= 6 × 20mm = 120mm.

7. Rebar placing :

When we tie the rebars in the lapping zone, the joggled part of the bar should be placed over the inner surface of the bottom bar (as shown in the above drawing ) to get a uniform clear cover from the concrete surface.

If you tie the joggled portion of the rebar over the outer surface of the bottom bar, then the lapping zone invades the concrete cover area provided for the bars.

Other Post

Surveying & Architects A unique platform of Civil Engineering

Surveying & Architects A unique platform of Civil Engineering