Different Types Of Stone Masonry Used in Construction

In this article we explain different types of Stone Masonry with full details and also Explain types of Rubble Masonry & Ashlar Masonry & also we explain important points for Stone Masonry, Surfacing of Stone Masonry, Joints of Stone Masonry, appliance use for lifting a stone…..

Must Read Full Article….

What is Stone masnry ?

Stone masonry is defined as a building masonry that is constructed by using stone in which stones are bonded together with the help of mortar.

Different Types of Stone Masonry

- Rubble masonry

- Ashlar Masonry

| Rubble Masonry | Ashlar Masonry |

|---|---|

| 1. Coursed rubble masonry | 1. Ashlar fine |

| 2. Uncoursed rubble masonry | 2. Ashlar rough tooled |

| 3. Random rubble masonry | 3. Ashlar quarry faced |

| 4. Dry rubble masonry | 4. Ashlar chamfered |

| 5. Polygonal rubble masonry | 5. Ashlar block-in course |

| 6. Flint rubble masonry | 6. Ashlar facing |

Rubble Masonry

This types of stone masonry uses stones of Irregular shape and size. The stones brought from the quarry are used directly in masonry or used in masonry work after breaking them with a hammer to the required size.

Size of the stone is less than 250 mm

The strength of rubble masonry depends on the following.

- Quality of mortar.

- Frequent use of through stone in masonry.

- Proper filling of mortar between stones.

Learn More

What Is Difference Between Pre-tension And Post-tension

1. Coursed Rubble Masonry

In this types of stone masonry, the height of stones is 5 cm to 20 cm. Masonry is done in layers. The height of the stones is the same in a certain level.

This type of masonry is done in Public houses, residential houses.

There are three types of Coursed rubble masonry.

- First class coursed rubble Masonry.

- Second class coursed rubble masonry.

- Third class coursed rubble masonry.

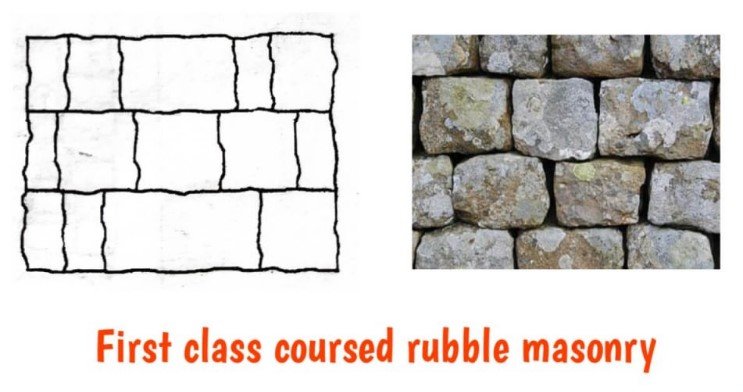

a. First class coursed rubble Masonry

-

In this stone masnry types, all the stones have the same height.

-

The height of each Course is the same.

-

The thickness of the Mortr joints should not exceed 10 mm.

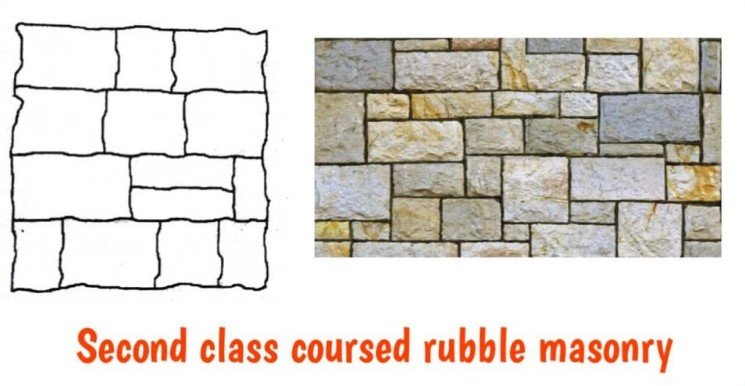

b. Second class coursed rubble masonry

-

In this types of stone masonry, the stones have different heights.

-

Not all courses have same height.

-

Only two stones are used to get a course height.

-

The thickness of the Mortar joints is 12 mm.

Learn More

How To Estimate Per Meter Weight Of Reinforcing Steel Bar

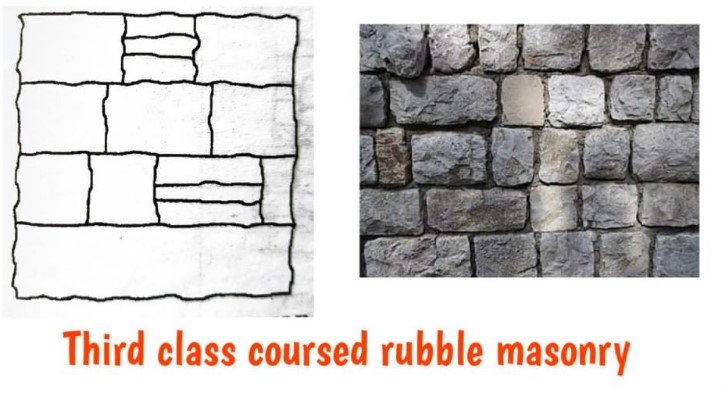

c. Third class coursed rubble masonry

-

In this types of stone masonry the stones have different heights.

-

The minimum height of the stone is 5 cm.

-

Not all layers are the same height.

-

Only three stones are used to get a course height.

-

The thickness of the mortar joints is 16 mm.

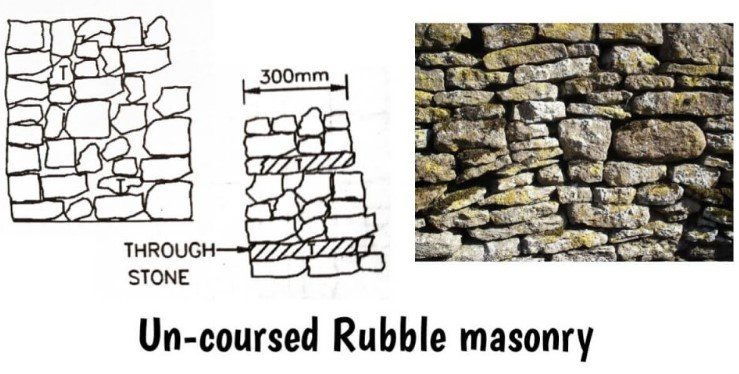

2. Un-coursed Rubble Masonry

-

This stone masonry types, Stones are not dressed. But, the corners of the stones which are obtained from the mine are removed with the help of a hammer and then used.

-

Masonry’s work does not occur in layers.

-

The cavities between the first sized large stones are filled with small stones.

-

The height of masonry should be equalized every 40 cm to 50 cm.

-

This types of stone masonry use in the compound walls, warehouses, garage, small houses, etc.

-

This types of masonry vary cheap.

Learn More

The Construction Risk Management Guide

3. Random Rubble Masonry

-

This types of stone masonry involve arranging stones of irregular shapes and sizes to create an aesthetic-looking wall.

-

If it is made with a hammer and the thickness of the joint is not more than 12 mm, it is called second class random rubble masonry.

-

This types of stone masonry is used for residential buildings, compound walls, warehouse etc.

Learn More

Building Estimation of Long Wall Short Wall And Center Line Method.

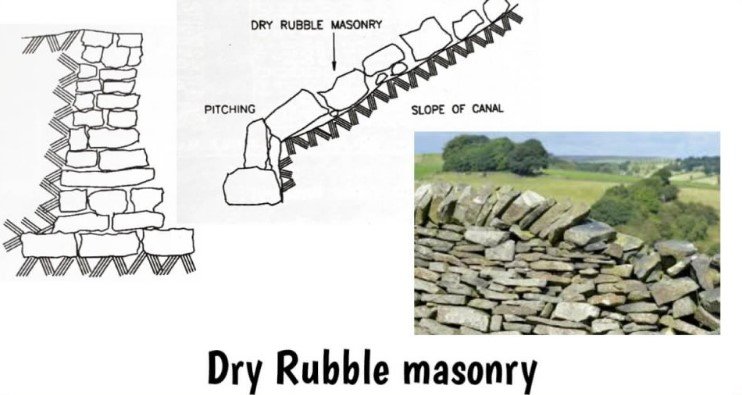

4. Dry Rubble Masonry

-

The masonry is similar to the third class coursed masonry, but does not use mortar.

-

This types of stone masonry is very cheap, but requires skilled labor.

-

This type of masonry used in compound wall.

-

Masonry of 50 cm length at the top and at the ends is done with mortar to prevent shifting of stones and make the work more rich.

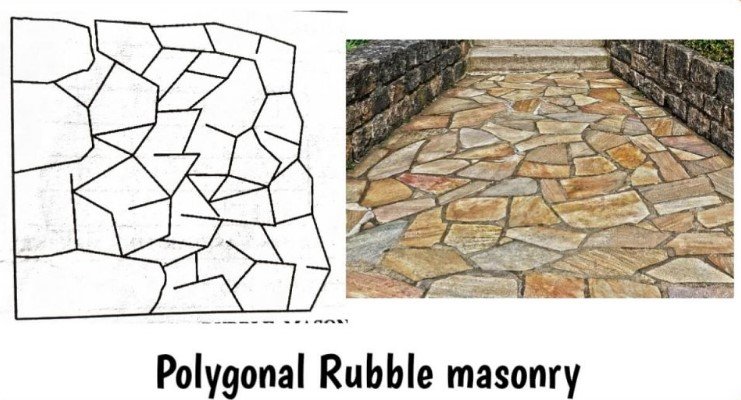

5. Polygonal Rubble Masonry

-

In this types of stone masonry, the stones are hammer dressed. The stones used in the surface are shaped into irregular polygons so that the joints on the surface appear to move irregularly in all directions.

-

This type of stone masonry requires more skill labors.

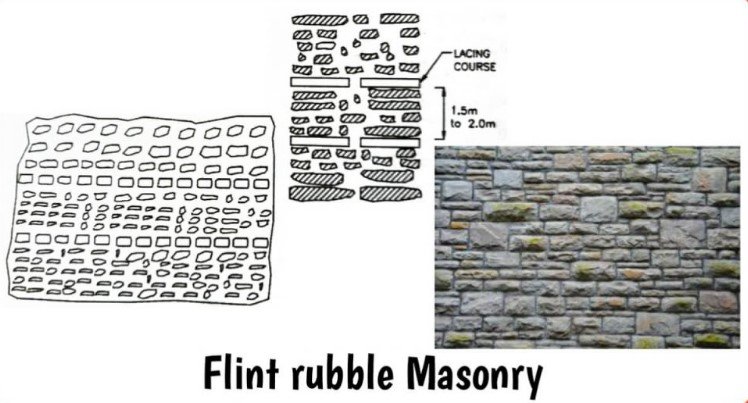

6. Flint Rubble Masonry

-

Flint is a silica stone. They are 80 mm to 150 mm thick and 50 mm to 300 mm long.

-

Such stones are hard, but break quickly.

-

The arrangement of the stones on the surface can be layered or non-layered.

-

A lacing course of bricks or long stones is placed at a distance of 2 m from the floor to increase the strength of the flint wall.

Learn More

A Guide on Estimation, Quantity Survey – Types of Estimate.

Ashlar Masonry

-

This types of masonry uses square or rectangular stones.

-

The height of the stones varies from 25 cm to 30 cm.

-

The length of the stone should not exceed three times the height.

The different types of Ashlar masonry are as follows.

- Ashlar fine.

- Ashlar rough tooled.

- Ashlar quarry faced.

- Ashlar chamfered.

- Ashlar facing.

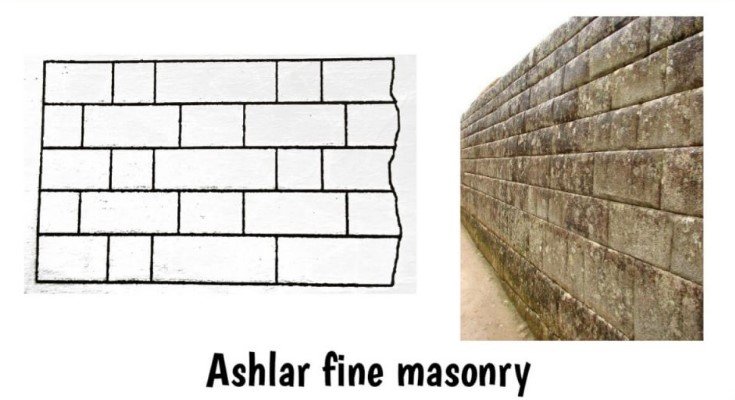

1. Ashlar fine

-

In this type of stone masonry, the stone is chisel-dressed on both sides and ends.

-

The height of the layer does not exceed 30 cm.

-

All course have the same height.

-

The thickness of the call joints does not exceed 3 mm.

-

Masonry has good aesthetic view.

-

Masonry has costly.

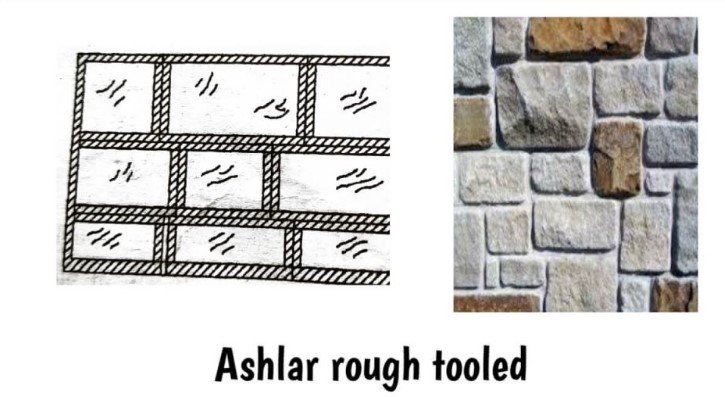

2. Ashlar Rough Tooled

-

This types of stone masonry has stone beds and sides chisel-dressed while the surface is rough with a tool.

-

The 25 mm wide strip on all four sides of the stone on the exposed face is made with a chisel while the middle part is rough with a tool.

-

The thickness of the mortar joints does not exceed 6 mm.

-

Such masonry is also called bastard ashlar.

3. Ashlar quarry faced

In this types of stone masonry, a 25 mm wide strip is made with chisel on all four sides on the surface visible outside the stone. When the middle part of this masonry surface is kept the same as extracted from the stone quarry.

Learn More

What Is Difference Between Pre-tension And Post-tension

Projection larger than 80 mm on the outer surface are removed with a hammer.

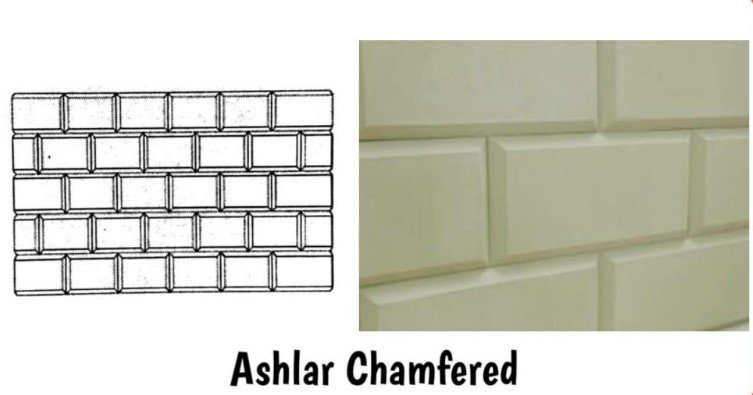

4. Ashlar Chamfered

In This types of stone masonry a 25 mm wide strip around the outer surface of the stone is made with chisel. The strip is chamfered at an angle of 45 degree to 25 degree to a depth of 25 mm.

Another 12 mm wide strip is carved around the middle surface. The middle part of this masonry surface is kept the same as extracted from the stone quarry.

Learn More

-

How Many Types Of Septic Tanks Based On Materials

-

How To Estimate Per Meter Weight Of Reinforcing Steel Bar

-

How To Calculate The Cutting Length Of Circular Stirrup

Projection larger than 80 mm on the outer surface are removed with a hammer.

5. Ashlar Block In Course Masonry

-

In this types of stone masonry the thickness of course is 20 cm to 30 cm.

-

The stone face is hammer dressed.

-

The thickness of the joints does not increase beyond 6 mm.

-

This type of masonry is used in heavy engineering constructions like maintenance wall, coastal wall, railway station, bridges etc.

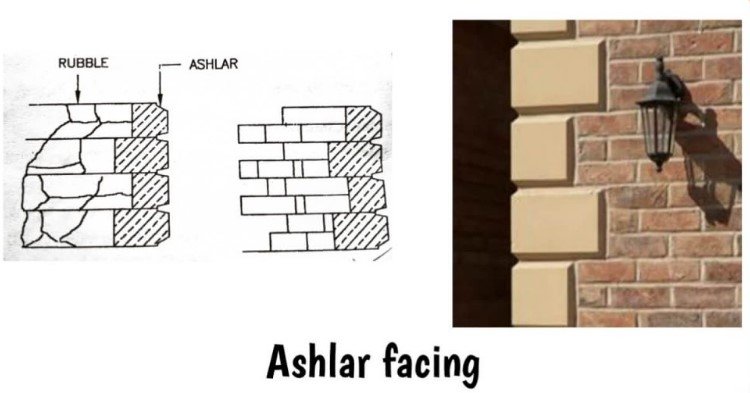

6. Ashlar facing

In this type of masonry, the outer part of the masonry is made of stone masonry and the back part is made of brick masonry. So that the good aesthetic view of Ashlar masonry can be obtained at low cost.

The height of the course should not be less than 20 cm.

For walls up to 75 cm thick, the bond stone should extend over the entire thickness of the wall.

Learn More

-

How To Estimate Per Meter Weight Of Reinforcing Steel Bar

-

How To Calculate The Cutting Length Of Circular Stirrup

Difference Between Dry Rubble Masonry and Random Rubble Masonry and Coursed Rubble Masonry

| Dry Rubble Masonry | Random Rubble Masonry | Coursed Rubble Masonry |

|---|---|---|

| 1. Irregular shape and size stones are arranged in an irregular layer without mortar. | 1. Irregular shape stones are arranged in parallel layers to provide good aesthetic view | 1. Irregular shaped and same size stones are arranged in parallel layers to provide a good aesthetic view |

| 2. Very Cheap | 2. Moderate Cost | 2. Very Costly |

| 3. Not required too skilled labors | 3. Required Skilled Labors | 3. Required Well Class skilled Labors |

| 4. Used to construct boundary walls in Farms, and open ground. | 4. Used to construct Residential buildings, Load-bearing walls, compound walls, warehouses, etc. | 4. Used to construct public houses, residential buildings, forts, etc. |

Tools Used in stone Masonry..

- Mason Hammer

- Club Hammer

- Spalling Hammer

- Stabling Hammer

- Point Chisel

- Claw Chisel

- Plane Chisel

- Bolster Chisel

- Drafting Chisel

Important points for stone masonry

-

The stone should be Insert in water before use. So that the stone does not suck the water from the mortar.

-

The stones should be well seasoned, hard, tough.

-

The stone should not have cracks, cavities etc.

-

In masonry the stone should be arranged on its natural bed.

-

The masonry work should be done using a proper bond. Vertical joints should not be in a row.

-

Use through stone where it is required.

-

Care should be taken not to cause tensile stress in stone masonry.

-

Good quality mortar should be used.

-

The masonry of the entire length of the wall must be done together. If this is not possible, steps or too things should be placed in the wall.

-

Chips, spalls should be used in masonry.

-

Double scaffolding should be used for masonry at higher heights.

-

The verticality of the wall during masonry should be checked with a plumbed.

-

Curing should be done for two weeks after completion of masonry.

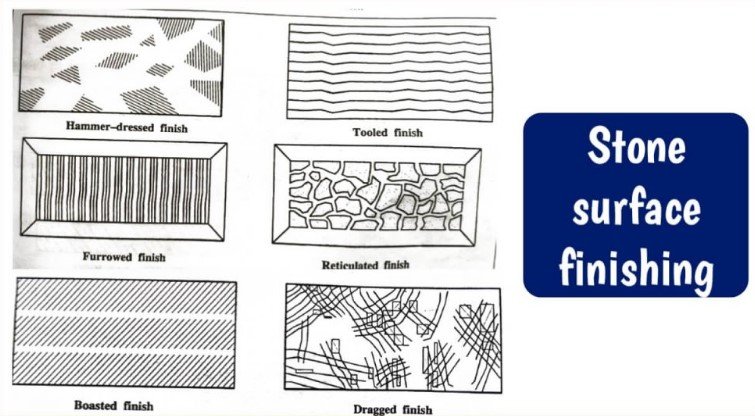

Stone surface finishing

Different types of stone surface finishing are as follows.

- Hammer dressed finish

- Dragged finish

- Tooled finish

- Plain finish

- Furrowed finish

- Axed finish

- Reticulated finish

- Punched finish

- Boasted finish

- Vermiculated finish

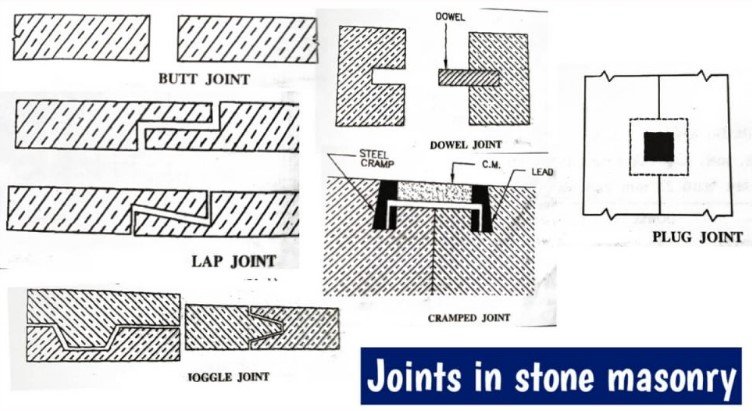

Joints in stone masonry

The various joints used in stone masonry are as follows.

- Butt or square joint

- Lap or Rebated joint

- Joggle or Tongued and Grooved joint

- Table joint

- Plugged joint

- Dowel joint

- Camp joint

1. Butt joint or Square joint

In this joint one stone is placed next to another stone. This type of joint is more commonly used in stone masonry

2. Lap or Rebated joint

In this type of joint, two stones are placed on each other and one stone is applied on top of the other. The length of the coating should not be less than 70 mm.

Learn More

-

How Many Types Of Septic Tanks Based On Materials

-

How To Estimate Per Meter Weight Of Reinforcing Steel Bar

-

How To Calculate The Cutting Length Of Circular Stirrup

3. Joggle or Tongued and grooved joint

- This type of joint has a projection at one end of the stone and a groove at the other end.

- In this type of joint one stone is not slip over another stone.

- This type of joint is less used because it is difficult to make and costly.

4. Dowel joint

- This type of joint has horizontal holes in two adjacent stones.

- Dowel is fit in both these halls.

- A dowel is a small piece of stone, gunmetal, bass, copper, etc.

- Dowell can be fitted with cement.

- Dowell are 10 to 15 cm long and 25 mm thick.

5. Cramp Joint

This type of joint uses a camp instead of a dowel. The camp is made of non-corrosive metals such as gunmetal, copper etc.

Two stones are arranged side by side and a diagonal hole is placed on the upper surface, in which the hole is filled with cement sheet or lime by arranging a cramp.

6. Plugged joint

In this type of joint, two stones are arranged side by side and both the stones are grooved. In this groove is poured molten lead or cement grout. So that the two stones joints together properly.

This type of joint is Used in cornice coping.

Appliances for stone lifting

As the weight of stone is very heavy, special equipment has been designed to lift it. The various tools used to lift the stone are as follows.

- Chain or Rope

- Chain dog

- Lewis

- Nippers or Tongs

- Pins

Learn More

H.S.E Interview Questions And Answers

1. Chain or Rope

The stone is placed in a sack or in a wooden plank box and tied with a chain or rope so that the edges and corners of the stone are not broken, then the stone is lifted by laborers with a pulley block.

2. Chain dog

The chain is arranged in a triangle. One dog is fitted at each of the two corners of the triangle. There are 20 mm deep pits between the sides. The pit is filled with dog hooks. Then pool the stone.

3. Lewis

A stone weighing a maximum of 1 ton can be lifted with a Lewis.

4. Nippers or Tongs

5. Pins

It has a pair of steel pins. Pins are hammered into the hole in the stone. When the stone is lifted, the pin becomes tight in the stone so that it is not pulled out.

Other Post

-

How To Estimate the Material for Concrete

-

Thumb Rules For Civil Engineers In Building Construction

-

Bar Bending Schedule for RCC Beam In Full Detail

To get more information, Visit Our Official website

Land Surveying & Architects

Surveying & Architects A unique platform of Civil Engineering

Surveying & Architects A unique platform of Civil Engineering