Why Crank Bars Are Provided In The Slab Construction

Now, let us look into some of the FAQs related to crank bars or bent-up bars in slab construction.

1. Why crank bars are provided in slab construction?

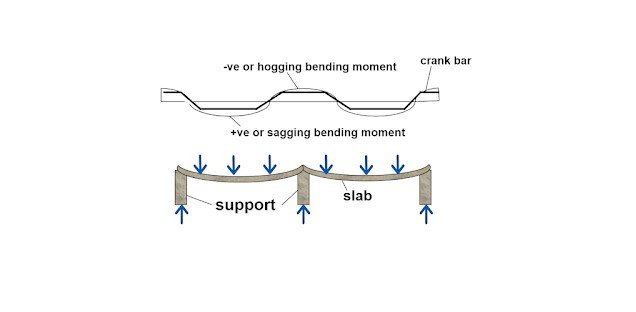

When the dead load of the slab and uniform live load over it act in the downward direction, the forces in the end support or continuous support act in the upward direction to counterbalance the slab load.

This action creates two types of bending moments in the structure. They are +ve or sagging bending moment & -ve or hogging bending moment as shown in the diagram below.

Crank bars are provided to resist these both types of bending moments. For your reference, I have included the crank bar in the bending moment diagram (see below) to clearly understand this concept.

As you can observe in the above drawing, the bottom reinforcement part of the crank bar resists the +ve or sagging bending moment, and the upper bent-up part of the crank bar tackles the -ve or hogging bending moment.

Learn More

Calculation Of Staircase Concrete And Bar Bending Schedule (BBS) | Staircase Reinforcement Details

2. What are the uses of crank bars in construction?

The crank bar

1. Helps in resisting bending moments.

2. Helps to withstand shear force i.e. maximum at the support.

3. Reduces the overall weight of reinforcement bars required in the slab.

4. Helps in reducing project costs.

5. Prevents the failure of the slab due to shear force.

3. Why do we provide alternative crank bars in slab reinforcement?

Learn More

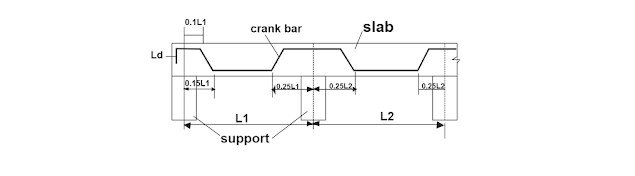

4. At what distance bent-up bars are cranked in a slab?

I have downloaded the drawing below that helps you to clearly understand the bent-up distance in a slab.

As you can observe in the above diagram, crank bars are bent up at a 45° angle with the bottom end is at 0.15L1 from the center of the end support. At the continuous support, crank bars bent-up end are at 0.25L1 & 0.25L2 distance on either side from the centerline of the support.

Other Post

-

Calculate Center To Center Distance Between The Bars In Column – Beam And slab

-

Bar Bending Schedule Of Plinth Beam

Surveying & Architects A unique platform of Civil Engineering

Surveying & Architects A unique platform of Civil Engineering