Steel Fiber Reinforced Concrete – Mix Design

Advantages & Disadvantages of Steel Fiber Reinforced Concrete

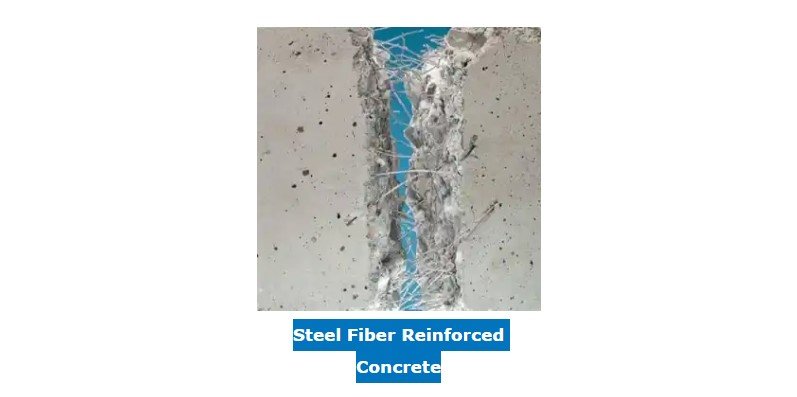

Steel Fiber Reinforced Concrete ( S.F.R.C ).

Steel Fiber Concrete is a type of ( RCC ) reinforced Concrete. Steel fiber reinforced concrete ( S.F.R.C ) as the name suggests that is made up of composite materials such as cement, sand, aggregate, water, gravel, steel fiber & admixture. In this concrete fiber, steel fiber is an additional ingredient.

Fiber is added into the concrete is 0.3 to 2.5% by its volume of the plain cement concrete. The diameter of the steel fiber is used in concrete is 0.25-mm to 0.75-mm. commonly round shape of the steel fiber is used.

In the steel fiber reinforced concrete adding steel fibers in the concrete mixer & transfer green concrete into the molds or cubes & then after compacting the concrete, lastly cure the cubes by any conventional method of the curing.

During the mixing of ingredients & during compacting the cubes are getting a high chance of the segregation, balling of the steel fiber, & bleeding of the concrete. Segregation is avoided by adding a uniform rate of the fibers. Also, it is more permeable.

Higher efficiency is required for mixing the ingredients, placing, compacting, conveying, & finishing steel-reinforced concrete.

Learn More

-

Overlapping of Steel in The Different Grade of Concrete

-

How to Calculate the Quantity of Cement Mortar In Brickwork and Plaster

-

Bar Bending Schedule For Reinforcement Beam

The main objective of adding the steel fibers are into the concrete is to improve the mechanical properties & structural properties, particularly flexural strength & tensile strength, ductility, wear & tear, post cracking strength of ( S.F.R.C ) is higher than any type of the concrete.

ISO 13270:2013 used for steel fiber reinforced concrete.

For the field experiments, steel fiber reinforced concrete is used for the runway slabs & that is reduced one-half thickness of the plain concrete slab just adding 2% of steel fiber.

Using the steel fiber reinforced concrete developed manhole cover in India by the structural Engineering Research center, Chennai.

The Cement Research Institute of the India is demonstrated the Steel fiber reinforced concrete for jet bays at Delhi airport.

The Steel fiber reinforced concrete is used for garage parking slabs at the Heathrow airport in London.

Various Types of the Fibers Are Used for Making Reinforced Concrete

- Steel fibers

- Glass fibers

- Synthetic fibers ( Nylon fibers & Polypropylene fibers )

- Natural fibers ( Sugar cane, jute, rice husk, bamboo and wood )

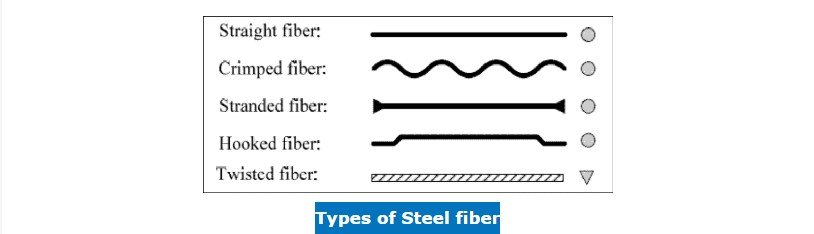

Types of the Steel Fiber for Reinforced Concrete

-

Straight fiber

-

Crimped steel fiber

-

Hooked steel fiber

-

Button end steel fiber

-

Twisted steel fiber

( S.F.R.C ) Is A Versatile Concrete Such As

-

Deck of bridge

-

Manhole cover

-

Highway lining

-

Tunnel lining

-

Runway

-

Window & doors frame

-

For staircase

-

Breakwater structure

-

Foundation block

-

Storage bins

-

Lightweight Structure

-

Shotcrete

-

For the construction of the workshop

-

Industrial Flooring

-

For Military Structure

-

For pre–fabricated elements

-

For commercial structure

-

For High resistance

-

For the construction of a spillway

-

For the construction of Dam

-

For Stabilization of rock slope

-

For explosion restive structure

-

For cavitation work

Benefits For Users

-

To minimize the risk of the cracking.

-

To reduce joint spalling.

-

To make high–impact resistance concrete.

-

To make stronger & more durable joints.

-

To increase the utility period of the structure.

-

To decrease the cost of the maintenance.

Advantages of the ( S.F.R.C )

- The Steel reinforced fibers concrete ( S.F.R.C ) is more durable, high in strength as compared to plain concrete.

- It is the good in impact resistance.

- It provides good resistance in torsion, shear force, & compression.

- It is improved surface resistance to abrasion & erosion.

- It is high in flexural strength & tensile strength.

- It is economical.

- In the steel fiber reinforce concrete many verities of the precast concrete units are available.

- ( S.F.R.C ) also helps to reduce the cross–sectional area of the structure and make it a lighter structure. Also, it saves the material.

- To increase the speed of the construction. So that saves time.

- To reduce shrinkage of the concrete.

- Steel fiber can reduce the slab thickness by up to 50 Percent.

Learn More

-

How To Estimate the Material for Concrete

-

Building Estimation of Long Wall Short Wall And Center Line Method.

-

A Guide on Estimation, Quantity Survey – Types of Estimate.

Disadvantages of ( S.F.R.C )

- During the rain–damaged slabs, allow both fibers and aggregate to be exposed.

- It is aesthetically not good.

- It adversely affects the work-ability of the concrete.

- It is heavy as compared to non–fiber concrete.

- Improper mixing can lead to balling of the fiber.

- The use of the Steel fiber is crucial to determine the amount of the fiber, type, length of the fiber, etc.

- Using the Steel fiber for fiber concrete is costly.

- Steel fiber leads to a corrosion effect.

Mix Design of ( S.F.R.C )

- The mix proportion of ( S.F.R.C ) is depend upon the various factor such as required strength, work-ability, particular job, cross sectional area etc.

- Many different types of the procedures are there for proportioning of ( S.F.R.C ) mix. This emphasizes the workability’s of concrete mix.

- Commonly mixes the higher cement contents & higher ration of the fine aggregate to coarse aggregate is required.

- So that the conventional type of the concrete mix design is not applicable to the steel fiber concrete. Generally to reduce the cement QTY , used fly ash up to 35% of the cement.

- In addition to improve work-ability of the concrete admixtures are used such as super plasticizers, water reducing admixture etc.

The proportion range of the normal weight steel fiber concrete is given below,

Property |

Mortar |

9.5 mm Max. aggregate Size |

19 mm Max. aggregate size |

Cement |

415 – 710 |

355 – 590 |

300- 535 |

Water cement ratio |

0.3 to 0.45 |

0.35 – 0.45 |

0.4 – 0.5 |

Fine aggregate / Coarse aggregate |

100 |

45 – 60 |

45 – 55 |

Entrained air |

7 – 10 |

4 – 7 |

4 – 6 |

Fiber content by volume Smooth steel |

1 – 2 |

0.9 – 1.8 |

0.8 – 1.6 |

Deformed steel |

0.5 – 1 |

0.4 – 0.9 |

0.3 – 0. |

Learn More

-

How to Calculate the Cost of Paint for one Room

-

How to Create The Design Of RCC Structures With Details

The empirically derived mix design proportion is used for the shotcrete work. Typical mix design for the fiber shotcrete is given below

Property |

Fine aggregate mixture |

9.5-mm aggregate mixture |

Cement |

446 – 559 |

445 |

Blended Sand |

1438 – 1679 |

697 – 880 |

9.5 mm aggregate |

700 – 875 |

|

Steel Fiber |

35 – 157 |

39 – 150 |

Accelerator |

varies |

varies |

Water cement ratio |

0.40 – 0.45 |

0.40– 0.45 |

Applications of the Steel Fiber Reinforce Concrete.

The use of the steel fiber concrete is widely used for a few years. So that it is difficult to categorize them, the most commonly used in pavement, slab casting, slab repairs, silica fume & runway so on.

Recently experimental works have been completed on the roller compacted concrete (R.C.C) reinforced with steel fibers.

The steel fiber is relatively expensive like 1 percent of the additions of steel fiber will approximately double the cost of the material so that steel fiber reinforced concrete is used in special applications.

Other Post

-

How To Calculate The weight of Steel With Formula

-

Basic Rule For Design Of Concrete Column

-

How To Calculate The Volume Of Concrete Triangular Pile Cap Having 3-Piles

Surveying & Architects A unique platform of Civil Engineering

Surveying & Architects A unique platform of Civil Engineering